Introduction

The semiconductor industry forms the backbone of modern electronics, playing a critical role in powering devices from smartphones to supercomputers. As we delve into the intricacies of this sector, we will explore the history, manufacturing processes, market dynamics, and future trends that shape the semiconductor landscape.

Historical Background

The origin of semiconductors can be traced back to the early 20th century with the discovery of semiconductor materials like silicon and germanium. The invention of the transistor in 1947 at Bell Labs marked a significant turning point, paving the way for the miniaturization of electronic components and the birth of modern computing.

Evolution of Semiconductors

- 1950s-1960s: The commercial production of integrated circuits (ICs) began, allowing multiple transistors to be placed on a single chip. This era witnessed the rise of companies like Fairchild Semiconductor and Texas Instruments.

- 1970s-1980s: The microprocessor revolution occurred, enabling the development of personal computers. Companies like Intel and AMD emerged as key players.

- 1990s-2000s: With the advent of the internet, demand for faster and more efficient semiconductors surged. Advanced fabrication technologies and the introduction of System on Chip (SoC) designs became commonplace.

- 2010-Present: The rise of mobile computing, artificial intelligence, and the Internet of Things (IoT) has further driven innovation and competition within the industry.

Manufacturing Process

The semiconductor manufacturing process is intricate and involves several stages:

1. Design Phase

Designing a semiconductor starts with determining the functionality required. Engineers utilize complex software tools to create circuit designs.

2. Wafer Fabrication

The primary material for semiconductors is silicon, often used in the form of wafers. The fabrication process includes:

- Photolithography: A process that transfers the circuit design onto the silicon wafer using UV light and specialized chemicals.

- Etching: The removal of unwanted material to define electronic structures.

- Doping: Introducing impurities to modify electrical properties.

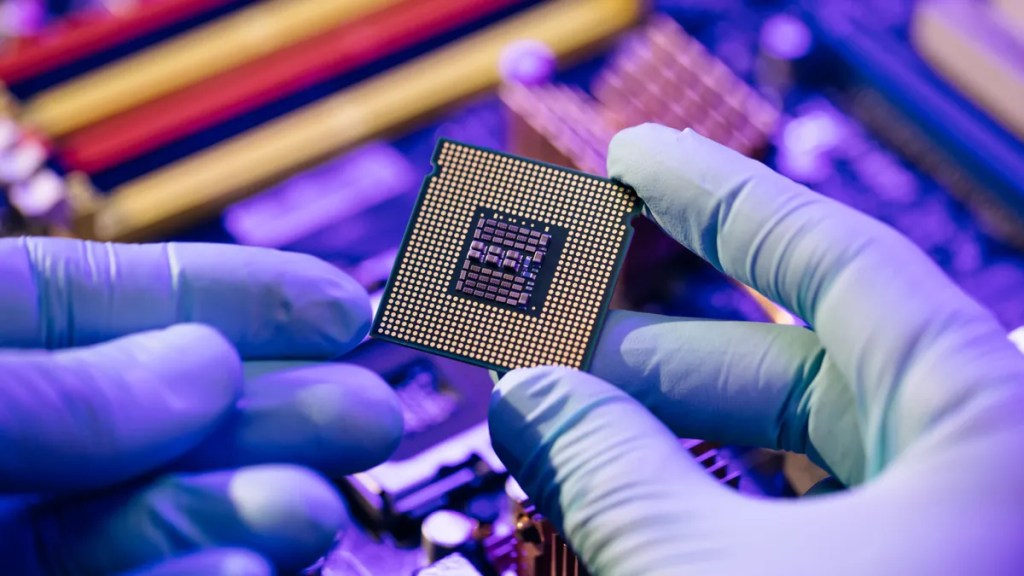

3. Assembly and Packaging

Once the wafer is processed, it is sliced into individual chips. Each chip undergoes testing and is then packaged to ensure protection and provide connections to external circuits.

4. Testing

The final stage involves rigorous testing to check for defects and ensure functionality. This process is crucial to maintaining quality and reliability.

Market Dynamics

Key Players

The semiconductor industry includes a mix of major players:

- Foundries: Companies like Taiwan Semiconductor Manufacturing Company (TSMC) and GlobalFoundries that focus on manufacturing semiconductors for other companies.

- Fabless Companies: Entities like Qualcomm and NVIDIA that design chips but outsource manufacturing to foundries.

- Integrated Device Manufacturers (IDMs): Companies like Intel and Samsung that design, manufacture, and sell their semiconductors.

Market Segments

The semiconductor market can be divided into several segments, including:

- Consumer Electronics: Smartphones, tablets, and laptops.

- Automotive: Chips for vehicles, including advanced driver-assistance systems (ADAS).

- Industrial: Applications in manufacturing and automation.

- Telecommunications: Infrastructure for mobile networks and data centers.

Global Trends

- Increased Demand: The growth of AI, 5G, and IoT technologies is driving demand for advanced semiconductors.

- Supply Chain Challenges: Recent global events have exposed vulnerabilities in supply chains, leading to shortages and increased prices.

- Geopolitical Tensions: Trade policies and international relations are shaping where and how semiconductors are manufactured, particularly between the U.S. and China.

Semiconductors Industry in India

The semiconductor industry in India is poised for substantial growth, driven by an increasing demand for electronic devices and a focus on self-reliance in technology manufacturing. As the backbone of modern electronics, semiconductors play a crucial role in various sectors, and India is increasingly recognized as an emerging hub in this domain.

Historical Context

Historically, India has had a modest presence in the semiconductor sector, primarily involved in the design and assembly of chips rather than manufacturing. However, with the rapid growth of the technology sector since the late 20th century, initiatives to stimulate domestic semiconductor capabilities have gained momentum.

Evolution of the Industry

- Early 2000s: India began focusing on developing its semiconductor design capabilities, with companies like Wipro and Tata Consultancy Services establishing design centers.

- 2010s: The government launched several initiatives to foster innovation and attract foreign investment, including the “Make in India” campaign. This period saw the establishment of design houses and the growth of fabless companies.

- 2020s: The Indian government’s recent push to build a robust semiconductor manufacturing ecosystem has led to increased interest from global semiconductor firms looking to invest.

Current Landscape

Key Players

The Indian semiconductor landscape features a mix of domestic and international players:

- Fabless Companies: Indian firms like Chipmonk Technologies and Intersil focus on chip design and outsource manufacturing.

- International Firms: Global players such as Intel, Qualcomm, and Texas Instruments have set up operations in India, contributing to the growth of the sector.

- Government Initiatives: The Indian government has announced financial incentives and policies to attract investments in semiconductor manufacturing and design.

Market Segments

The semiconductor market in India can be segmented into various areas such as:

- Consumer Electronics: Increasing smartphone penetration and demand for smart devices drive semiconductor needs.

- Automotive Electronics: The rise of electric vehicles and connected cars necessitates advanced semiconductor solutions.

- Telecommunications: With the rollout of 5G technology, there is a growing requirement for semiconductor components in network infrastructure.

Challenges and Opportunities

Key Challenges

- Manufacturing Infrastructure: The lack of localized semiconductor fabrication facilities poses a significant hurdle for the industry.

- Investment Requirements: Establishing manufacturing units demands substantial investment and skilled manpower.

- Global Supply Chain Dependencies: India’s semiconductor sector relies heavily on the global supply chain for raw materials and equipment, which can lead to vulnerabilities.

Emerging Opportunities

- Government Incentives: The Indian government’s announcement of a $10 billion fund to bolster semiconductor manufacturing presents a considerable opportunity for growth.

- Increasing Demand: With the growth of digital India, the demand for semiconductors is projected to rise dramatically, providing a fertile ground for new investments.

- Focus on R&D: By investing in research and development, India can enhance its capabilities in cutting-edge semiconductor technologies.

Future Outlook

The future of India’s semiconductor industry appears promising, with anticipated advancements in technology and infrastructure:

- Local Manufacturing: Efforts towards establishing semiconductor fabs could lead to domestic production, reducing reliance on imports.

- Skilled Workforce Development: Education and training in semiconductor design and manufacturing will be essential to meet the industry’s growing demands.

- Collaboration with Global Players: Partnerships with established global semiconductor firms can provide India with the technological expertise necessary for growth.

India’s semiconductor industry stands at a pivotal juncture, with favorable government policies and robust market demand. By addressing the existing challenges and leveraging opportunities, India can establish itself as a significant player in the global semiconductor landscape, ensuring its position in the future of technology.

Future Outlook

The future of the semiconductor industry holds great promise, driven by ongoing innovation. Key trends to watch include:

- Advanced Materials: Research into materials beyond silicon, such as graphene and gallium nitride, may revolutionize semiconductor performance.

- 3D Chip Technologies: Stacking chips vertically could improve performance and reduce space requirements.

- Sustainability: The industry is under pressure to adopt environmentally friendly practices, from manufacturing to end-of-life recycling of semiconductors.

Conclusion

The semiconductor industry is vital to the technological advancements of our time. As we stand on the brink of a new era defined by AI, IoT, and beyond, understanding the complexities and dynamics of this sector is crucial for navigating the future landscape of technology.

Hashtags

Here are some relevant hashtags for the semiconductor industry:

- #Semiconductors

- #Technology

- #Electronics

- #Microprocessors

- #IntegratedCircuits

- #AI

- #IoT

- #Manufacturing

- #Innovation

- #SupplyChain

- #DigitalIndia

- #5G

- #Graphene

- #Sustainability

- #TechTrends

Leave a comment